What is Gas Nitriding and Why is it Important?

Gas nitriding is a surface hardening heat treatment process used to enhance the wear resistance, fatigue strength, and corrosion resistance of steel components. This process involves diffusing nitrogen into the surface of special steel parts at temperatures between 500°C to 530°C in the presence of ammonia gas.

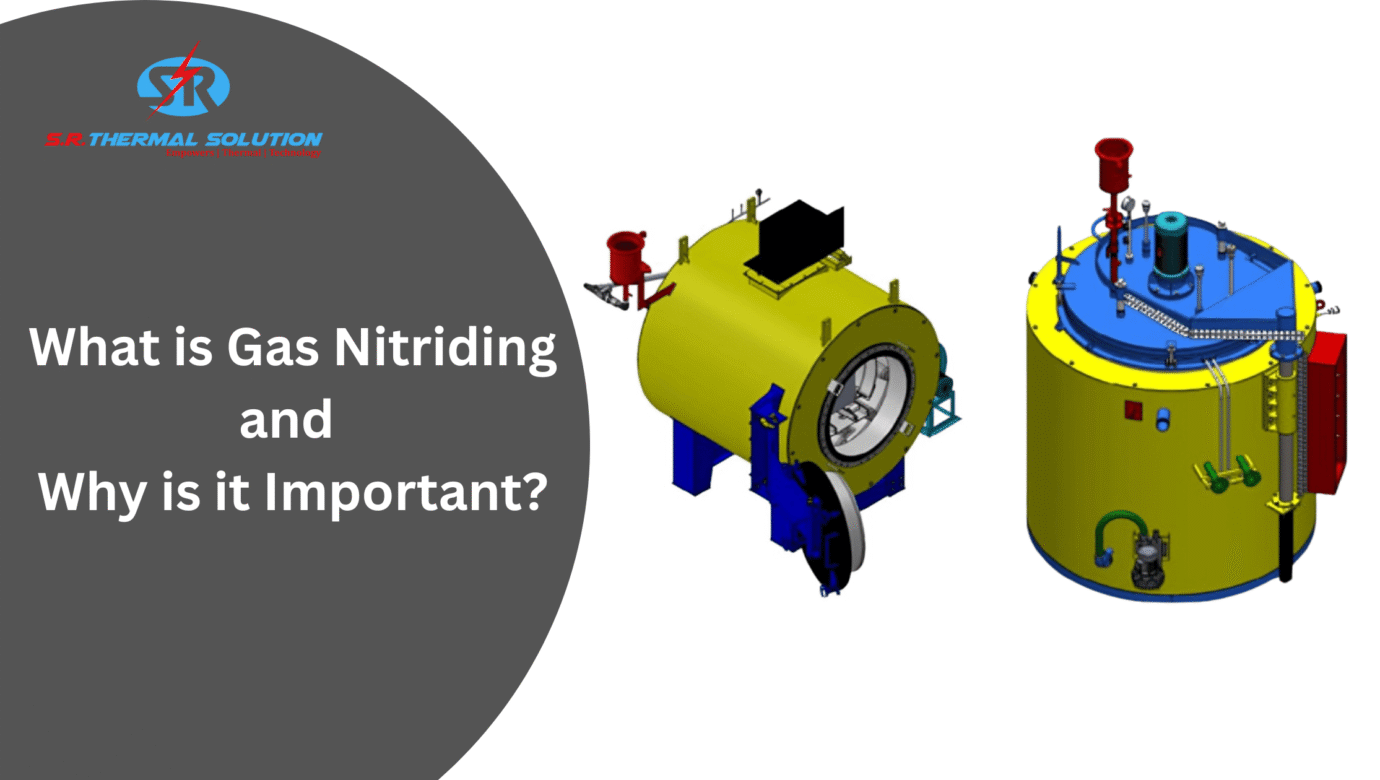

At S.R. Thermal Solution, we design and manufacture advanced Gas Nitriding Furnaces that ensure precise control, energy efficiency, and consistent results for a variety of industrial applications.

The Gas Nitriding Process

In gas nitriding, steel parts are exposed to ammonia gas inside a specially designed furnace. The nitrogen from the ammonia diffuses into the steel surface and reacts with alloying elements to form hard nitrides.

Temperature Range: 500°C – 530°C

Treatment Duration: Typically 90 to 96 hours (longer than carburizing processes).

Result: A hard, wear-resistant layer that significantly extends the life of steel components.

This process is especially suited for high-speed steel tools like taps, drills, and reamers, improving their durability by 100% to 200%.

Why Choose Gas Nitriding?

Enhanced Wear Resistance – Protects critical components from abrasion and wear.

Corrosion Protection – Increases resistance to rust and chemical attacks.

Dimensional Stability – Performed at lower temperatures, minimizing distortion.

Improved Fatigue Strength – Extends the service life of tools and components.

Gas Nitriding Furnaces by S.R. Thermal Solution

We specialize in manufacturing Horizontal and Vertical Type Gas Nitriding Furnaces, equipped with:

- 7” HMI + PLC Control Systems

- SCADA Integration for real-time monitoring

- Thyristor Controlled Heating for energy efficiency

- Kn Atmosphere Control for accurate nitriding potential

We also design and customize furnaces based on client-specific requirements and production needs.

Applications of Gas Nitriding

- Automotive Components (gears, crankshafts, camshafts)

- Aerospace Tools and Parts

- Hot Work Tool Steels (H grades)

- Aluminium Extrusion Dies

- Industrial Machinery

Why S.R. Thermal Solution?

✅ Advanced Technology

✅ Tailor-Made Designs

✅ Reliable After-Sales Support

Trusted Gas Nitriding Furnace Manufacturer in India

S.R. Thermal Solution delivers world-class heat treatment solutions to industries worldwide. From precision engineering to custom-built furnace systems, we help you achieve superior surface hardening results.